Khoá nối xích 3/8” GUNNEBO G-10-10, dùng cho xích 10mm

Tình trạng:

Còn hàng

Khoá nối xích 4 tấn GUNNEBO G-10-10 dùng cho xích 10mm

Thông tin sản phẩm

Tên sản phẩm : Khóa nối xích

Model : G-10-10

Nhà sản xuất : Gunnebo/ Thủy Điển

Xuất xứ : Thủy Điển

Chất liệu : Chế tạo bằng thép hợp kim cấp 10, dùng với xích hợp kim cấp 10

Đường kính thân : 11 mm

Khả năng chịu tải : 4 tấn

Trọng lượng : 0.336 kg

Tất cả khóa nối xích Gunnebo đều có Chứng chỉ thử tải của Gunnebo và Giấy chứng nhận xuất xứ hàng hóa của Phòng thương mại Thụy Điển.

[Xem tiếp]

Thông tin sản phẩm

Tên sản phẩm : Khóa nối xích

Model : G-10-10

Nhà sản xuất : Gunnebo/ Thủy Điển

Xuất xứ : Thủy Điển

Chất liệu : Chế tạo bằng thép hợp kim cấp 10, dùng với xích hợp kim cấp 10

Đường kính thân : 11 mm

Khả năng chịu tải : 4 tấn

Trọng lượng : 0.336 kg

Tất cả khóa nối xích Gunnebo đều có Chứng chỉ thử tải của Gunnebo và Giấy chứng nhận xuất xứ hàng hóa của Phòng thương mại Thụy Điển.

Chọn loại đặt mua

Chọn loại đặt mua

Gọi ngay 0912.124.679 để có được giá tốt nhất!

Khoá nối xích 4 tấn GUNNEBO G-10-10

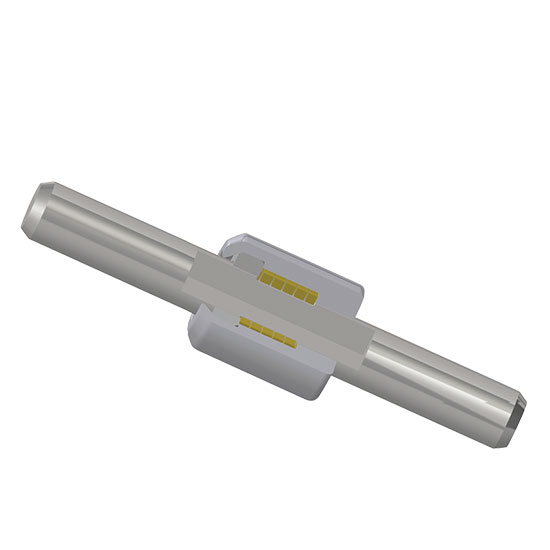

Back in 1952 Gunnebo Industries launched the Coupling G-link. This invention

changed the industry of lifting equipment. Prior to the G-link the standard was

to use all-welded chain slings, an expensive and time consuming process as

each and every chain sling ordered had to be assembled in the chain factory.

With the G-link chain slings could be assembled in local sling shops closer to

customers, creating more effective and flexible processes.

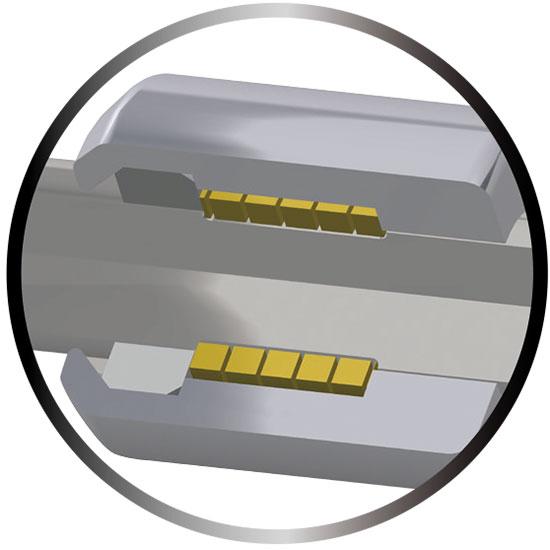

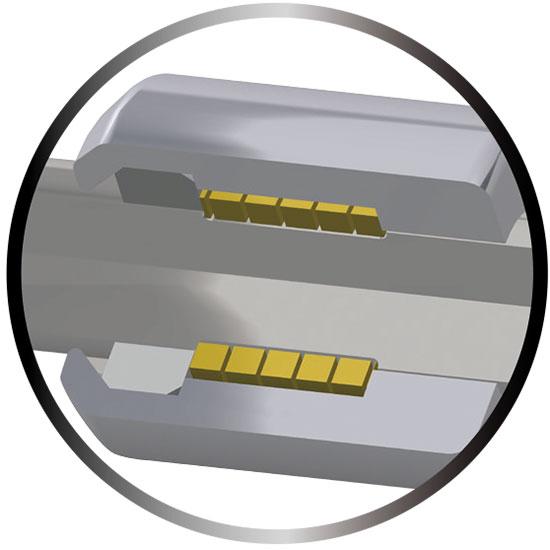

Besides a perfect design the G-link is equipped with a special pin retention

system. The pin has a recession in the middle where the locking bush holding a

helicoil shaped spring lies. The design of the pin, spring, and bush guarantees

safe retention of the locking bush, in case the wire of the spring should break.

Clear markings

• Country of origin.

• Traceability code.

• Model, size and grade.

Quality is top priority

• Fatigue tested.

• Forged alloy steel.

• Quenched and tempered.

• Steel from european suppliers.

• 100 % proof load of each G-link.

• 100 % Eddy current testing of pins.

• 100 % dimension control of pins with vision technology.

Safety is ourhighest priority

• To keep the pin securely in place every loop of the square shaped wire locking spring actively creates maximum locking effect.

• Every part of the locking spring – even if the wire should break – is still active to hold the pin.

Fluorescent color

• For high visibility in the field.

• Powder coated.

The special pin

• The pin has a recession in the center to give maximum locking effect.

• Safe retention of the locking bush.

• The pins are made in an automatic turning machine.

• Batch and grade marking in the center of all G-links.

Heavy duty locking bush

• Thick walls and washer protecting the spring.

• Permanently pressed together in an automated process, reducing risk of breakage.

• Square shaped stainless steel spring.

• Elektrogalvanized or stainless steel depending on model.

Thông số kỷ thuật

Back in 1952 Gunnebo Industries launched the Coupling G-link. This invention

changed the industry of lifting equipment. Prior to the G-link the standard was

to use all-welded chain slings, an expensive and time consuming process as

each and every chain sling ordered had to be assembled in the chain factory.

With the G-link chain slings could be assembled in local sling shops closer to

customers, creating more effective and flexible processes.

Besides a perfect design the G-link is equipped with a special pin retention

system. The pin has a recession in the middle where the locking bush holding a

helicoil shaped spring lies. The design of the pin, spring, and bush guarantees

safe retention of the locking bush, in case the wire of the spring should break.

Clear markings

• Country of origin.

• Traceability code.

• Model, size and grade.

Quality is top priority

• Fatigue tested.

• Forged alloy steel.

• Quenched and tempered.

• Steel from european suppliers.

• 100 % proof load of each G-link.

• 100 % Eddy current testing of pins.

• 100 % dimension control of pins with vision technology.

Safety is ourhighest priority

• To keep the pin securely in place every loop of the square shaped wire locking spring actively creates maximum locking effect.

• Every part of the locking spring – even if the wire should break – is still active to hold the pin.

Fluorescent color

• For high visibility in the field.

• Powder coated.

The special pin

• The pin has a recession in the center to give maximum locking effect.

• Safe retention of the locking bush.

• The pins are made in an automatic turning machine.

• Batch and grade marking in the center of all G-links.

Heavy duty locking bush

• Thick walls and washer protecting the spring.

• Permanently pressed together in an automated process, reducing risk of breakage.

• Square shaped stainless steel spring.

• Elektrogalvanized or stainless steel depending on model.

Thông số kỷ thuật

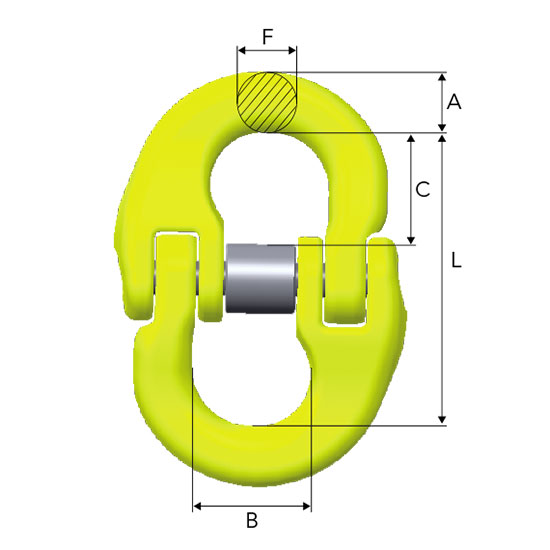

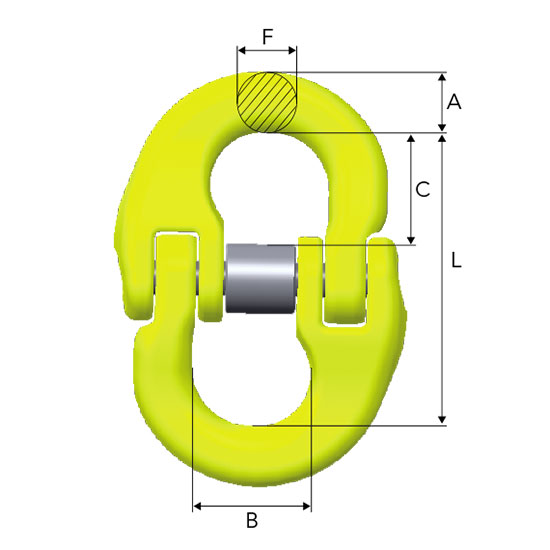

| Code | WLL t | L | B | F | A | C | Weight kgs |

| G-6-10 | 1.5 | 45 | 15 | 7 | 8 | 16 | 0.09 |

| G-7-10 | 2.0 | 56 | 18 | 9 | 11 | 22 | 0.161 |

| G-8-10 | 2.5 | 56 | 18 | 9 | 11 | 22 | 0.17 |

| G-10-10 | 4.0 | 68 | 25 | 11 | 13 | 26 | 0.336 |

| G-13-10 | 6.7 | 89 | 29 | 15 | 17 | 33 | 0.759 |

| G-16-10 | 10.0 | 106 | 36 | 19 | 20 | 40 | 1.366 |

| G-20-10 | 16.0 | 125 | 43 | 23 | 26 | 44 | 2.727 |

| G-22-10 | 20.0 | 152 | 50 | 26 | 28 | 59 | 3.48 |

| G-26-10 | 27.0 | 161 | 58 | 32 | 34 | 61 | 5.67 |

| G-32-10 | 40.0 | 200 | 70 | 38 | 40 | 77 | 9.95 |

Ý kiến bạn đọc